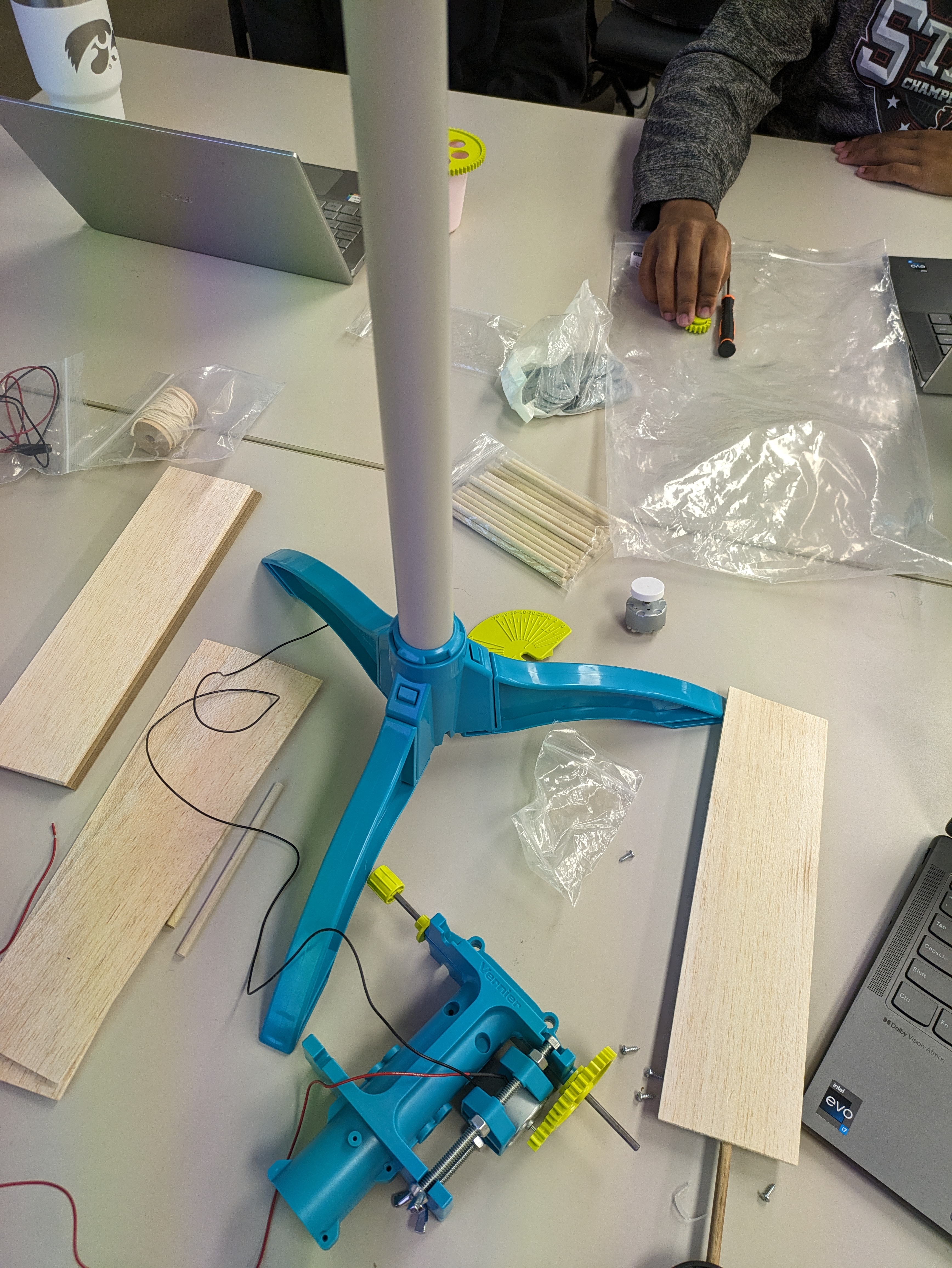

The purpose of this project is to design a windmill with minimal given constraints. This includes the freedom to discover the most optimal design components to improve the following: efficiency and energy output. Throughout the longevity of this project, variables such as blade shape, blade size, blade angle, blade material, and gear size will be adjusted in varying manners in order to reach maximum efficiency and power.

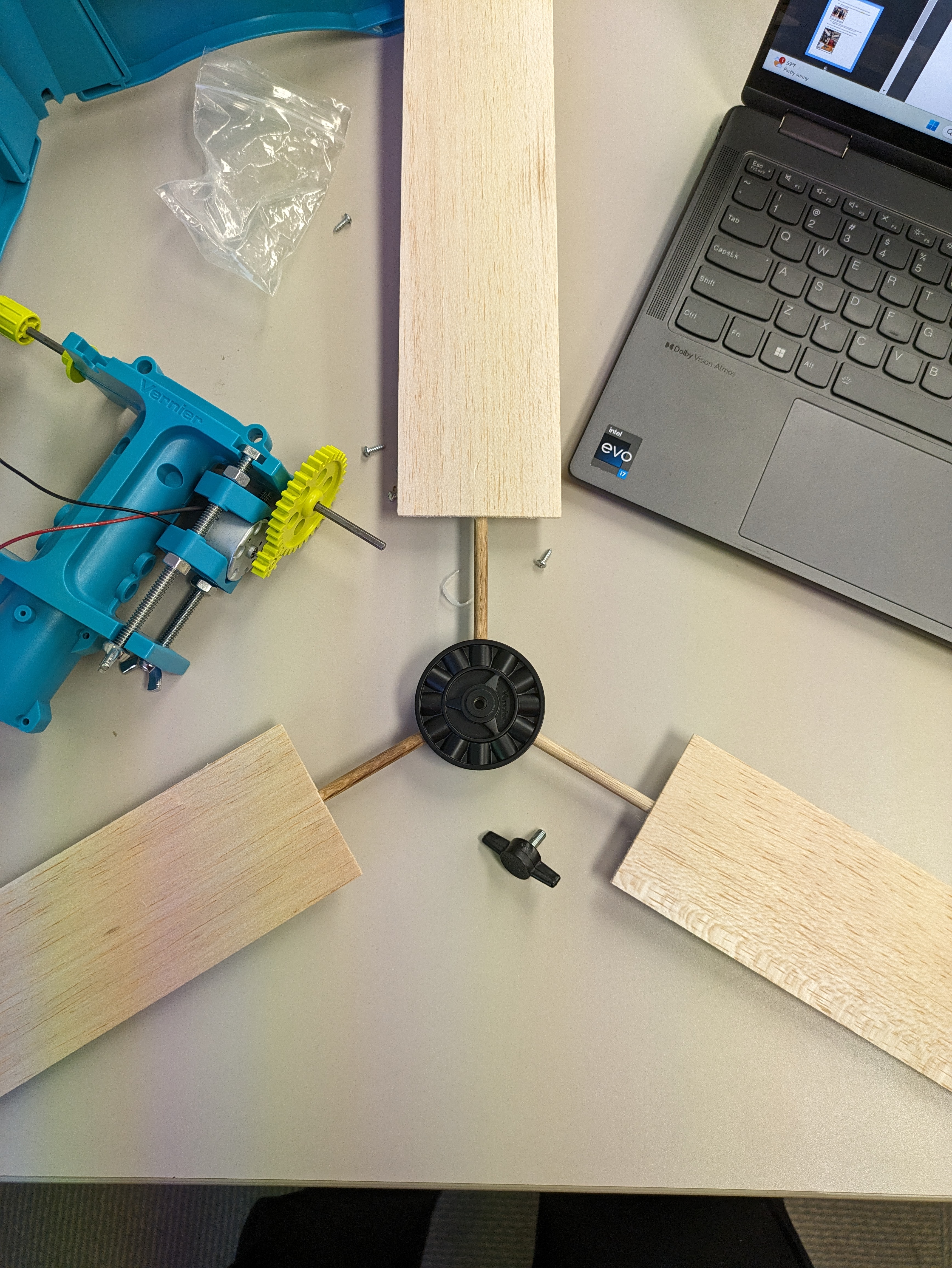

During the investigation, the team observed several factors to determine the most optimal blade material out of our options of cardboard, styrofoam, and balsa wood. We took note of the mass, density, volume, flexion, and power output of each material in order to determine the most suitable material. From this, the team determined that the best-performing blade was the balsa wood.

From the testing that the team has done so far, we have determined that: the most optimal blade angle tested is 15 degrees, the most ideal blade material is balsa wood, and the most efficient number of blades is 3. As we progress more through our investigation and experimentation, the team should be able to conclude the most ideal gear size and blade shape. Essentially, there is a plethora of data that is still to be collected to make the most ideal wind turbine possible with what is given.